Check out our new Product Documentation Library, located in the Support section of our website.

We have drawings and user manuals for past and current industrial monitors, as well as installation instructions for our other industrial products.

Check out our new Product Documentation Library, located in the Support section of our website.

We have drawings and user manuals for past and current industrial monitors, as well as installation instructions for our other industrial products.

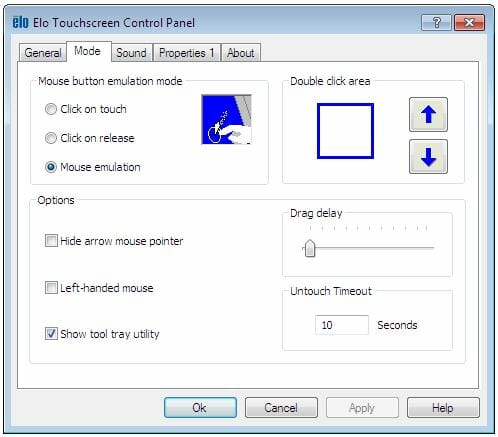

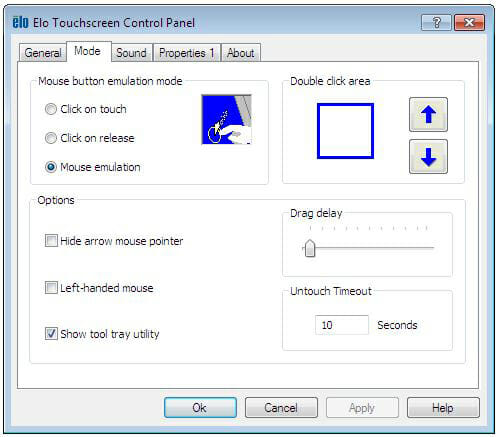

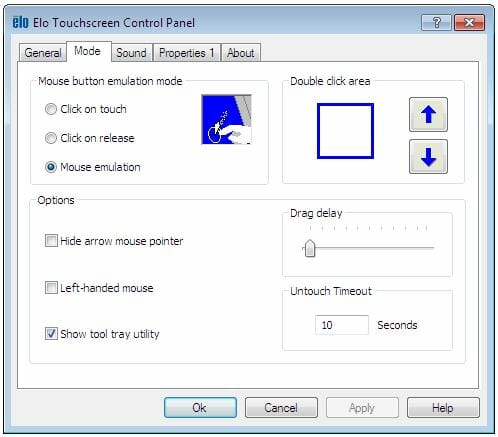

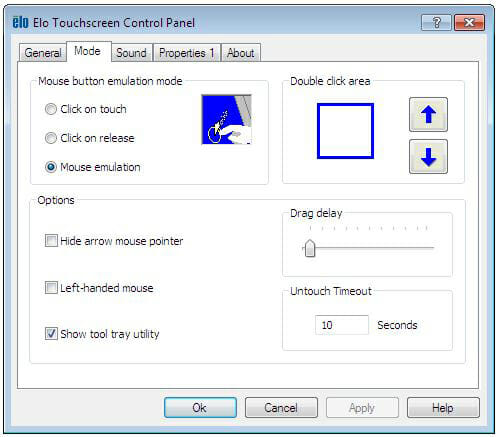

Depending on the environment, there are different requirements for user interfaces and how people need to interact. Recognizing this, Elo added a few features to their drivers that provide some advanced functionality to enhance usability for very specific purposes.

More and more often, our industrial touch screen customers are taking advantage of the open source Linux operating system, Ubuntu. Ubuntu has evolved into a versatile, easy-to-configure environment with a large community following and massive support from the company Canonical. We have seen a steady increase in calls from customers leveraging Linux in industrial environments, and in recent years Ubuntu has been leading the charge. In addition to the standard Elo-provided Linux driver, Ubuntu users now have a very simple touch screen driver solution that requires no new software.

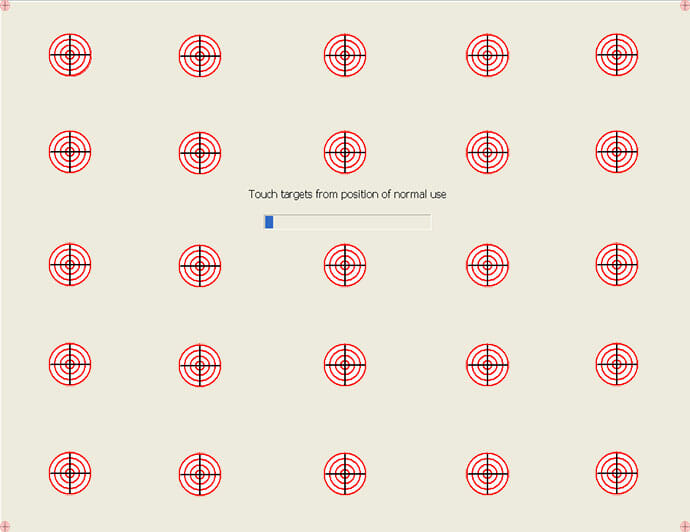

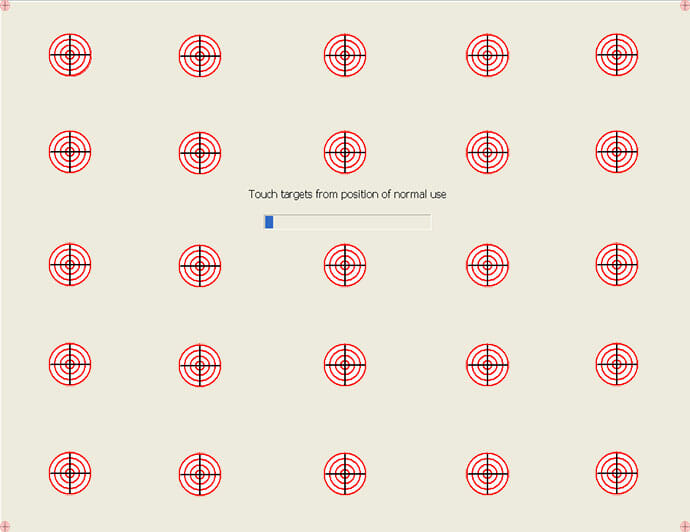

A demonstration of the Cursor Edge Acceleration feature available with Elo touch screen drivers.

A common problem for any fully enclosed NEMA 4/4X, IP65/66 rated display is exactly how to get the cables in and out of the enclosure while maintaining a water-tight seal. This problem has been approached in a variety of ways by equipment suppliers, but usually the solution involves either conduit, some sort of compression gland, or watertight external connectors with custom mated cables.

In most typical applications, Hope Industrial touch screens are used to be part of a PC-based HMI configuration, performing some type of PC-based control of an industrial process. The programs that generate these automation interfaces are generally designed with a very simple interface: large on-screen buttons allow simple interaction to a busy, often gloved worker. Generally, the user does not interface with the underlying PC operating system. To operate this type of application, the touch screen does no more than simply pass single “clicks” to the computer, which responds as if a mouse button was clicked.

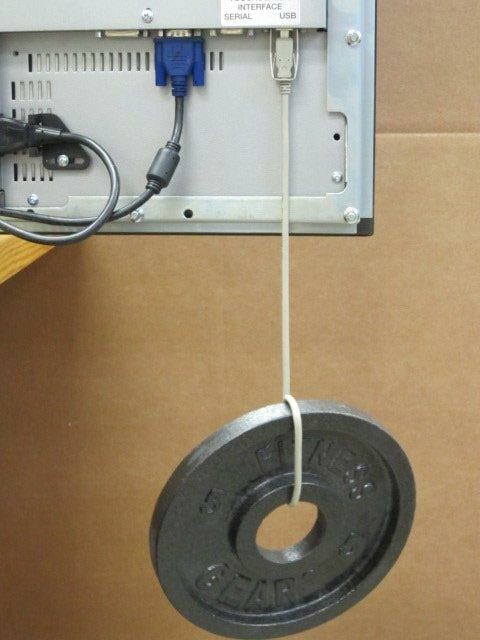

Cable connections between computers and peripherals on the factory floor are expected to hold tight during the rigors of operator movement and vibration that is not typical of office environments.

After 12 years in the industrial monitor and touch screen business – and over 40,000 monitors shipped worldwide – Hope Industrial Systems is happy to announce our new logistics center in the United Kingdom to better support the UK and Europe.

Thanks to our loyal customers, Hope Industrial Systems has outgrown our space once again. Watch as we break down the wall to our expanded office facilities.

As a rule of thumb, we recommend calibrating your industrial touch screen if the cursor is more than 0.25″ from the exact center of the point of touch. Doing so will increase the accuracy of the touch response and can make it easier to touch objects with pinpoint precision.